Written by:

Tina Brown

Imagine picking up a beautifully designed brochure, only to look closer in horror at all of the blurry images and smudged text. It's unlikely that such a piece would leave a positive impression on you, so imagine how your customers would feel - this is why built-in quality control measures are crucial.

Implementing print into your business can take time, especially when it comes to ensuring that the final products meet professional expectations. You will often lack control over the printing process and have limited autonomy when it comes to the quality of the printed material, so take baby steps. Starting with the basics and having some knowledge and criteria around print quality can make a world of difference.

We'll delve into the, seemingly impossible, challenges of maintaining print quality, and its inevitable impact on your brand's image and reputation, providing practical tips to navigate the world of print quality control. By the end of this voyage, you'll have gained the gems of information needed to make informed decisions and ensure captivating, top-notch print materials.

Quality control, in printing, refers to the systematic processes and measures implemented to ensure that the printed materials meet predetermined standards of excellence. It involves thorough inspections, checks, and tests at various stages of the printing process to avoid any shipwrecks before they happen. By conducting quality control, you can rest assured that the delivery of your print materials will be visually appealing, accurate, and consistent.

Pantone matching and machine colour calibration are essential aspects of quality control in printing. Pantone matching ensures consistent colour reproduction, especially for branding materials, where precise colour accuracy is crucial. Machine colour calibration means the presses printing your materials are set to the industry standards, meaning you will get the colour you expect.

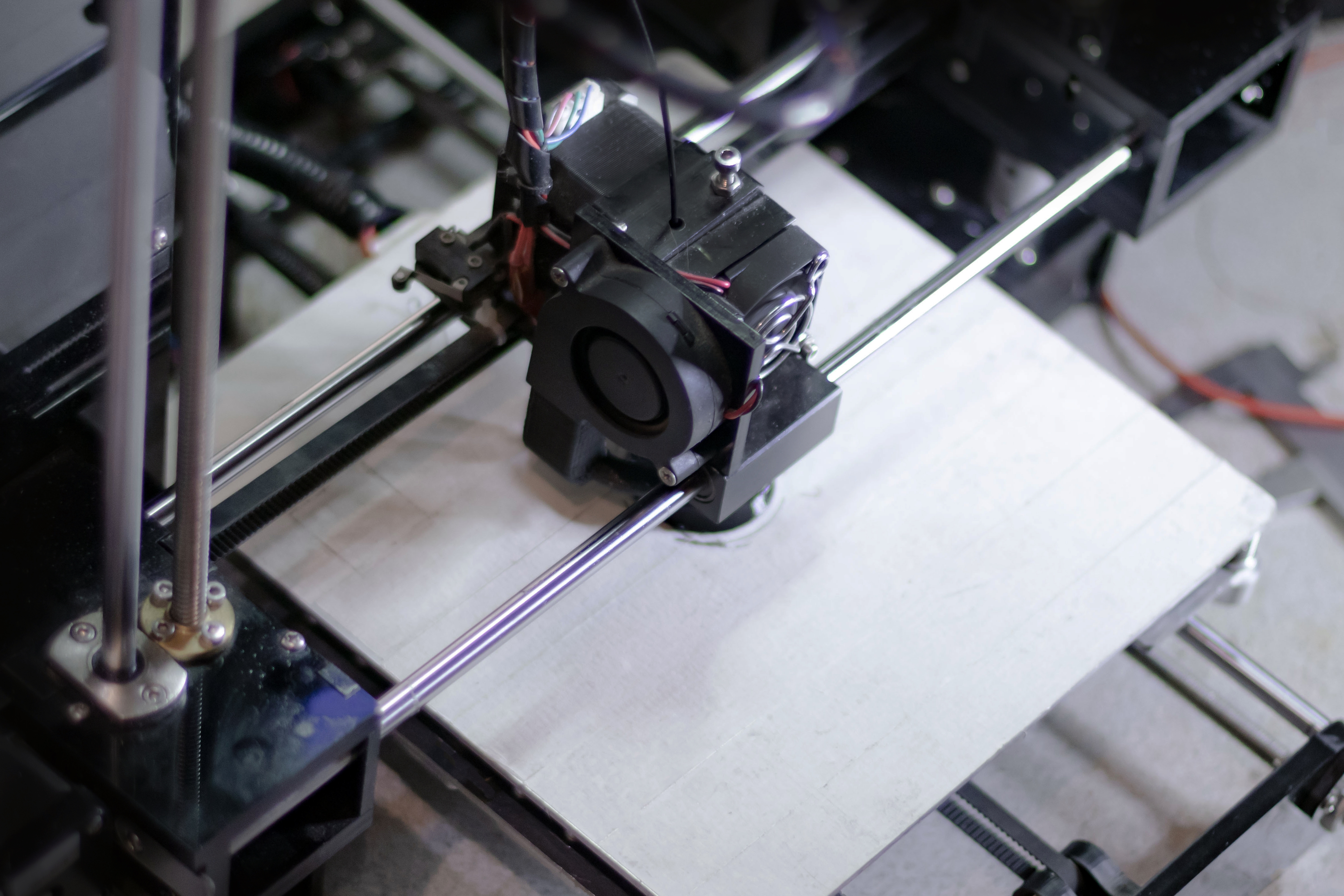

High-resolution images are crucial to avoid distortions in the final print. Preflighting is often used to verify the quality of images used in the artwork and helps identify any low-resolution or improperly formatted images, allowing for adjustments or replacements before sending your artwork to print.

A press pass involves being physically at the printing facility, magnifying glass in hand, to inspect and approve the first printed piece before the rest of the order is produced. It allows for a close, real-world examination of print quality, colour accuracy, registration, and any other critical aspects. By conducting press passes, any potential issues can be picked up early on allowing adjustments to be made, ensuring consistent quality throughout the print run.

Mock-ups serve as fully finished examples of the item being produced. They provide a tangible representation of the final product, allowing for a thorough evaluation of its appearance, layout, and functionality. By reviewing mock-ups, any discrepancies or any tweaks to dimensions and overall layouts can be made before moving on to a full production sample. 3 reasons why you should practise quality control in printing

If you want your brand to be taken seriously you need to invest the extra money and time nit-picking any faults and discrepancies. This will only serve you in the future by;

Implementing quality control measures prevents costly reprints and wastage, ensuring that printed materials meet standards and optimise return on investment.

Proactively addressing printing errors and quality issues streamlines the process, minimising delays, and reworks, and enabling timely delivery.

By prioritising quality control, you can achieve consistent, visually stunning, and accurately printed materials that positively impact their bottom line and brand perception. Start prioritising quality control to ensure that your printed materials meet your desired standards, leaving a positive impact on your customers and minimising costs.

While terms like "quality control" may sound overly technical, you don't have to get lost in the ocean of terminologies, specifications and technologies, with the right print partner like Summit Creative, we can take this mammoth task off your hands and save you the headache, with a fully comprehensive printing process from start to finish, designed for your needs. Summit to think about…

Roger Genis

Amari West London

Linsey Briggs

CEF

Steve Hudson

Howarth Timber

Hannah Sherriff

Mainline

West Midlands Safari Park

FREE advice, insights and good vibes only - it's a no spam zone over here!

Unit 6, Maisies Way

South Normanton

Derbyshire

DE55 2DS

T: 01623 625222